Machine To Crusher Rock Into Powder Crushing Process

.jpg)

The Ultimate Guide to Rock Crushers Mellott

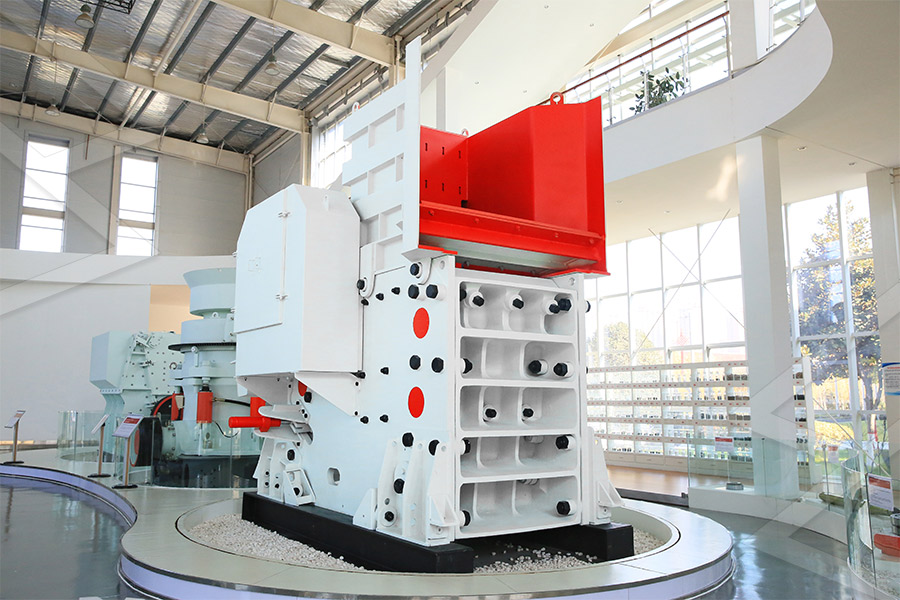

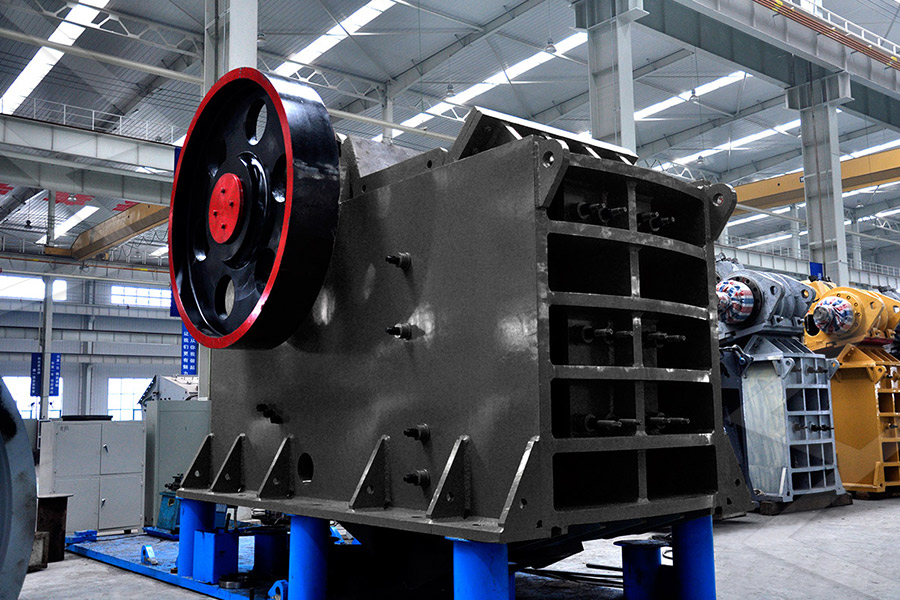

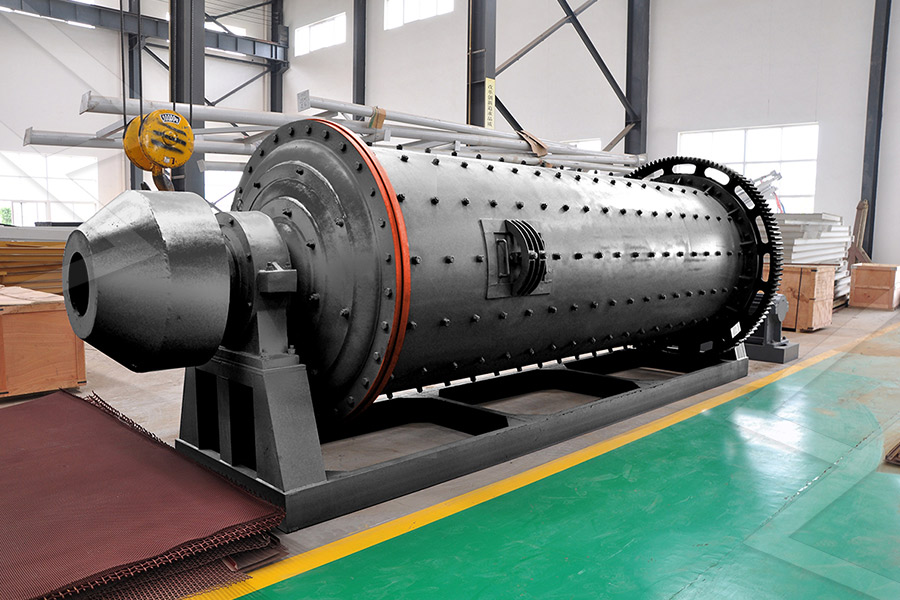

2024年5月30日 Rock crushing equipment plays a pivotal role in many industries From mining to construction, these powerful machines are at the heart of it all They break down large rocks into smaller, manageable pieces This process is 2017年4月24日 Bag your crushed rock sand and put it through a device known as a vibrating pulveriser This will crush your sand into fine dust A vibrating pulveriser is a large metal box How To Grind Stone Into Powder Sciencing2024年7月24日 Rock crushing machines function by applying mechanical force to break down rocks into smaller, more manageable pieces They utilize various mechanisms, including Rock crushing machines: transforming rocks into valuableLevstal has a broad range of crusher equipment including units that turn larger rocks into gravel or up to salt or powder sizing We offer several options for every need Our experienced Rock Crusher Machine: Mining Crusher Levstal

.jpg)

Rock Crushing Machines Technological Advances KB

2024年11月22日 The technological advances in rock crushing machines have translated into significantly increased productivity These machines can process large volumes of material in Stedman's Lump crushing equipment can reduce lumps created in the production, storage or transportation of bulk solids and powders without the dust We provide dry material systems engineering and expertise in a variety of areas including Aggregate Rock Crushing Equipment2022年5月14日 The crushing process in these crushers involves feeding large size rocks into its crushing chamber through hopper which form an acute angle between the fixed jaw plate and Stone Crushers: A Technical Review on Significant Part of2024年9月6日 The double roller sandmaking machine, also known as a roller crusher, is a mining machinery that integrates various technologies It performs fine crushing and sandmaking operations This machine has a reasonable structure, small size, and high efficiency, which make it popular However, is the sand produced by the roller sandmaking machine Double Roller Crusher Machine For Sand Making Eastman Rock Crusher

.jpg)

Types Of Rock Crushers And When To Use Them

2023年1月16日 Knowing what type of rock crusher to use for your project is essential in order to complete projects with maximum efficiency and minimal risk Understanding the Different Stages of Rock Crushing Rock crushing is an machine to crush rock into powder, process crusher machine to crush rock into powder 264 Views stone powder making machine Crushing Screening Plants liming Heavy Industry is professional in manufacturing stone powder making machine for mines and quarriesIf you want to know stone powder making machine price or Crushed Rock Stone Powder Making Machine Crusher Mills2023年2月15日 Limestone crushers: Crushing process one uses a jaw crusher, cone crusher and impact crusher (or sand maker) Crushing process two uses a heavy hammer crusher Crushing process three uses a roller crusher Crushing process: Crushing process one 1 Coarse crushing: Quartz is sent to a jaw crusher through a vibrating feeder for primary crushing;Which Crusher Is Suitable for Your Hard Rock? Fote 2024年11月7日 The vibrating feeder is responsible for the supply of rock dolomite, transporting the dolomite raw materials to the jaw crusher and cone crusher for crushing, and crushing them into particles with the required size present, the common dolomite powder in the market mainly includes 200mesh, 325mesh, 425mesh, 800mesh and 1250mesh To process How to Process Dolomite: Dolomite Crushing And Grinding

.jpg)

How to Crush Stones: A Comprehensive Guide Fote

2024年7月19日 Hardness is a key factor in choosing the appropriate stone crusher, as different stones naturally have different hardness levels Hard stones, such as granite and basalt, usually require powerful jaw crushers and cone crushers for effective crushing The crushing process for some softer rocks is simpler, as they require less crushing force2024年3月12日 The ultrafine grinding machine for dolomite powder has comprehensive mechanical crushing performance such as roller pressing, grinding, and crushing The equipment can form an independent and complete production system with strong systematicity, from the crushing, conveying, and powdermaking to the collection, storage, and packaging of Dolomite Crushing Process And Grinding Equipment2 天之前 Of course, there are also different styles of rock pressionstyle jaw and cone crushers, for example, fit into the various stations in a crushing circuit (depending on factors like the sizes, varieties, and hardness of the rock you need to Types of Rock Crushers Quarry Crushing Equipment Kemper2024年4月22日 The jaw crusher has a deep crushing chamber with no dead zone, and the discharge is adjustable Cone crusher As a secondary crushing process, a cone crusher is a better choice The cone crusher is suitable for crushing fine bentonite and achieve better results Impact crusher The impact crusher is equipment with internal grates and a Bentonite Processing Plant And Grinding Machine Eastman Rock Crusher

.jpg)

How to Process Dolomite: Dolomite Crushing And Grinding

2023年1月13日 In the crushing process of dolomite, jaw crusher is the mostly widely used coarse crushing equipment, and its performance characteristics in production include: The sand making machine is used for the fine crushing and shaping treatment, and crush the dolomite into grain size meet the requirements To process dolomite into powder with 2023年6月27日 This setup is a barite processing plant configured with a vibrating grizzly feeder, jaw crusher, log washer, spiral sand washer, vibrating screen, and belt conveyors The materials under the grizzly bar of the What Is The Process Of Barite? Eastman Rock Rock crusher machines Levstal has a broad range of crusher equipment including units that turn larger rocks into gravel or up to salt or powder sizing We offer several options for every need Our experienced engineering team designed and developed a rock crushing machine line designated to medium as well as largesized applications Mostly Rock Crusher Machine: Mining Crusher LevstalUse heavy machinery, like wheel loader, to load the raw rock material into the best rock crusher’s feed hopper or chute Avoid overloading the hopper, as this can cause jams or damage the crusher machine for stone Maintain a consistent and controlled flow of material into the simple rock crusher Start the Crushing ProcessHow to Choose A Rock Crusher? AIMIX GROUP

.jpg)

How to Choose a Rock Crusher PowerScreening Equipment

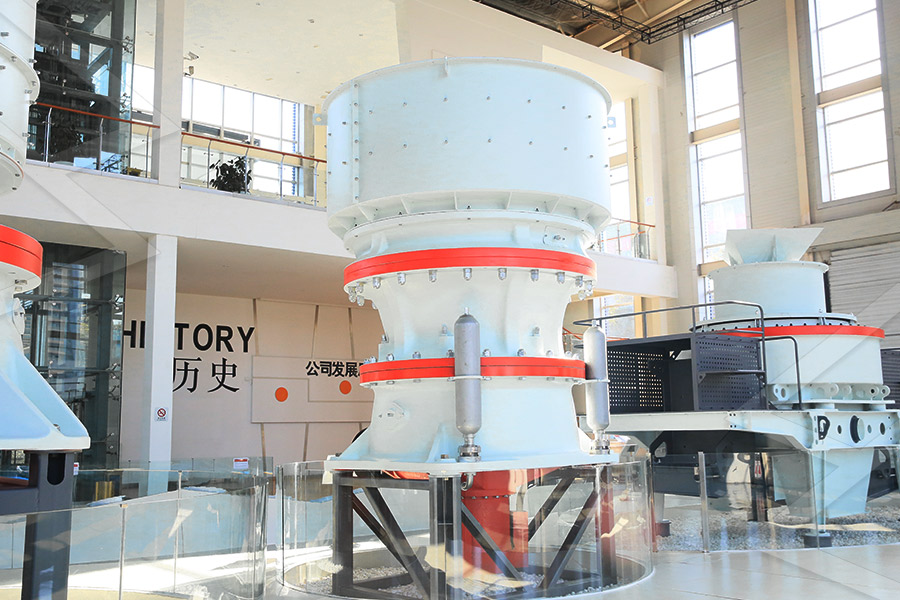

As with jaw crushers, these machines are compression crushers that use a stationary and moving piece of steel to break up the material Cone crushers use a rotating head to crush the rock within a steel bowl After initially being broken down in this manner, the material will travel through a narrow opening at the bottom of the bowl to achieve a finer grain size2021年9月6日 2 Wheel sand washer + fine sand recycling machine After the materials are crushed for sand making, we can arrange wheel sand washer equipment at the lower section of the sand making machineThe wheel sand washer equipment can clean the excess stone powder, soil and impurities in the machinemade sand, which has the characteristics of good cleaning Separation and Recovery of Stone Powder in Machinemade The first stage: crushing screening – three stage closedcircuit crushing Large pieces of iron ore are uniformly sent to the jaw crusher or coarse crushing mobile station by the vibrating feeder for coarse crushing; the coarsely crushed iron ore is screened by the vibrating screen and sent to the singlecylinder hydraulic cone crusher for processing Medium crushing: The iron ore material Iron Ore Processing Solution Eastman Rock Crusher2024年8月2日 Producing basalt rock powder involves several types of machines for crushing, grinding, and classifying the rock into a fine powder Here is a list of the essential machinery used in this process: Essential Machinery: Basalt Rock Powder Making MachinesPrimary Crusher: Jaw Crusher: Suitable for primary crushing of large basalt rocksBasalt Rock Powder Making Machines sbmmill

.jpg)

Rock Crushing 101: A Beginner's Guide Senya Crushers

Overcoming Common Challenges in Rock Crushing Rock crushing presents unique challenges, such as: Environmental regulations: Rock crushing operations must comply with local, state and federal regulations governing emissions, dust, noise and water use, among other things Highefficiency equipment that minimizes resource usage and contains machine to crusher rock into powder crushing process process dolomite into powder process crusher mining small machine to crusher rock into powder crushing process what is the process of mining dolomite Shanghai In the automatic equipments dolomite mining machines and dolomite crusher are also includedpowder crushing machine CapabuildFor example crushed material for road base and fill The main kinds of crushing machines for secondary processing are discussed below Cone crushers Cone crushers are one of the main choices for secondary crushing A cone crusher Types of Crushers: What You Need to Know2023年4月10日 2 Secondary crushing: Basalt materials (≤150mm) are sent to the cone crusher by belt conveyor for further crushing 3 Screening: The vibrating screen is used for reasonable screening, and the unqualified stones are 7 Mysteries of Basalt and How to Process Basalt

How to Process Dolomite Rock and What Is It

2024年10月14日 Because dolomite is brittle and has high hardness (harder than limestone), it is easy to scratch with iron, so it needs twostage crushing by a jaw crusher and a cone crusher 1 Coarse crushing: After mining, large dolomite 2024年1月23日 The vibrating feeder transports the raw gypsum material to the jaw crusher for crushing The materials reach the feed fineness of the grinding machine and enter the following process Step 2: Grinding small stones to stone powder Gypsum that meets the requirements for grinding fineness enters the gypsum particle silo by a bucket elevatorGypsum Powder Grinding And Processing Plant Equipment2024年7月24日 The evolution of rock crushing machines Rock crushing technology has seen remarkable advancements since its inception Early devices were rudimentary, relying on basic mechanical principles to break down rocks Over time, technological innovations have led to the development of sophisticated machines capable of handling a variety of materials with Rock crushing machines: transforming rocks into valuable2023年1月2日 Rock Crusher Machines Improve Each Stage Of The Crushing Process Understanding each stage of rock crushing is essential for the efficient operation of rock quarries and other related industries For instance, during the primary stage, rock size must be monitored carefully to ensure that only rocks that are within certain size parameters are The Stages of Rock Crushing Mellott

.jpg)

The Complete Guide to Primary Crushing, Secondary Crushing

2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of the comminution 2023年12月14日 By combining coarse and fine crushing operations to complete the crushing process Impact Crusher; The impact crusher can handle materials with a side length of 100500 millimeters or less and has a highpressure resistance of up to 350 MPA It has the advantages of a high crushing ratio and producing cubic particles after crushingFeldspar Powder Crushing Grinding Production Line EquipmentThe quartz sand making process is divided into three stages: coarse fine crushing, sand making screening, and sand washing recycling The first stage: coarse fine crushing The materials are uniformly fed by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushingQuartz Crushing Solution Eastman Rock Crusher2024年9月6日 The double roller sandmaking machine, also known as a roller crusher, is a mining machinery that integrates various technologies It performs fine crushing and sandmaking operations This machine has a reasonable structure, small size, and high efficiency, which make it popular However, is the sand produced by the roller sandmaking machine Double Roller Crusher Machine For Sand Making Eastman Rock Crusher

Types Of Rock Crushers And When To Use Them

2023年1月16日 Knowing what type of rock crusher to use for your project is essential in order to complete projects with maximum efficiency and minimal risk Understanding the Different Stages of Rock Crushing Rock crushing is an machine to crush rock into powder, process crusher machine to crush rock into powder 264 Views stone powder making machine Crushing Screening Plants liming Heavy Industry is professional in manufacturing stone powder making machine for mines and quarriesIf you want to know stone powder making machine price or Crushed Rock Stone Powder Making Machine Crusher Mills2023年2月15日 Limestone crushers: Crushing process one uses a jaw crusher, cone crusher and impact crusher (or sand maker) Crushing process two uses a heavy hammer crusher Crushing process three uses a roller crusher Crushing process: Crushing process one 1 Coarse crushing: Quartz is sent to a jaw crusher through a vibrating feeder for primary crushing;Which Crusher Is Suitable for Your Hard Rock? Fote 2024年11月7日 The vibrating feeder is responsible for the supply of rock dolomite, transporting the dolomite raw materials to the jaw crusher and cone crusher for crushing, and crushing them into particles with the required size present, the common dolomite powder in the market mainly includes 200mesh, 325mesh, 425mesh, 800mesh and 1250mesh To process How to Process Dolomite: Dolomite Crushing And Grinding

How to Crush Stones: A Comprehensive Guide Fote

2024年7月19日 Hardness is a key factor in choosing the appropriate stone crusher, as different stones naturally have different hardness levels Hard stones, such as granite and basalt, usually require powerful jaw crushers and cone crushers for effective crushing The crushing process for some softer rocks is simpler, as they require less crushing force2024年3月12日 The ultrafine grinding machine for dolomite powder has comprehensive mechanical crushing performance such as roller pressing, grinding, and crushing The equipment can form an independent and complete production system with strong systematicity, from the crushing, conveying, and powdermaking to the collection, storage, and packaging of Dolomite Crushing Process And Grinding Equipment2 天之前 Of course, there are also different styles of rock pressionstyle jaw and cone crushers, for example, fit into the various stations in a crushing circuit (depending on factors like the sizes, varieties, and hardness of the rock you need to Types of Rock Crushers Quarry Crushing Equipment Kemper2024年4月22日 The jaw crusher has a deep crushing chamber with no dead zone, and the discharge is adjustable Cone crusher As a secondary crushing process, a cone crusher is a better choice The cone crusher is suitable for crushing fine bentonite and achieve better results Impact crusher The impact crusher is equipment with internal grates and a Bentonite Processing Plant And Grinding Machine Eastman Rock Crusher