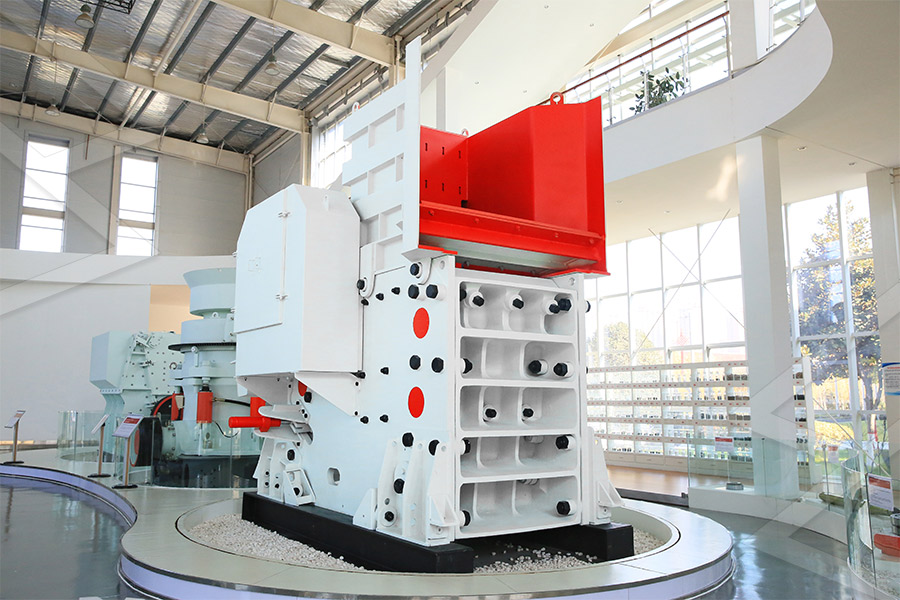

Secondary Jaw Crusher Jaw Crusher

)D`ERF`389RMI4.jpg)

Primary Crusher vs Secondary Crusher: Understanding Their

2023年2月28日 The primary crusher is usually a jaw crusher or a gyratory crusher, which operates by compressing the material between two surfaces The jaw crusher works by Secondary crushing is the second stage in the comminution process and involves The Complete Guide to Pri2019年1月1日 This paper compares the use of jaw and impact secondary crushing for producing coarse recycled aggregates from concrete wastes, obtained from road pavement and Concrete aggregates properties crushed by jaw and impact secondary Nordberg® C80™ jaw crusher is conventionally used as a primary or secondary crusher to prepare the material feed for the following steps of size reduction process Due to its compact size, Nordberg® C80™ jaw crusher has proven to Nordberg® C80™ jaw crusher Metso

Jaw Crushers AGGRETEK Jaw Crushers for

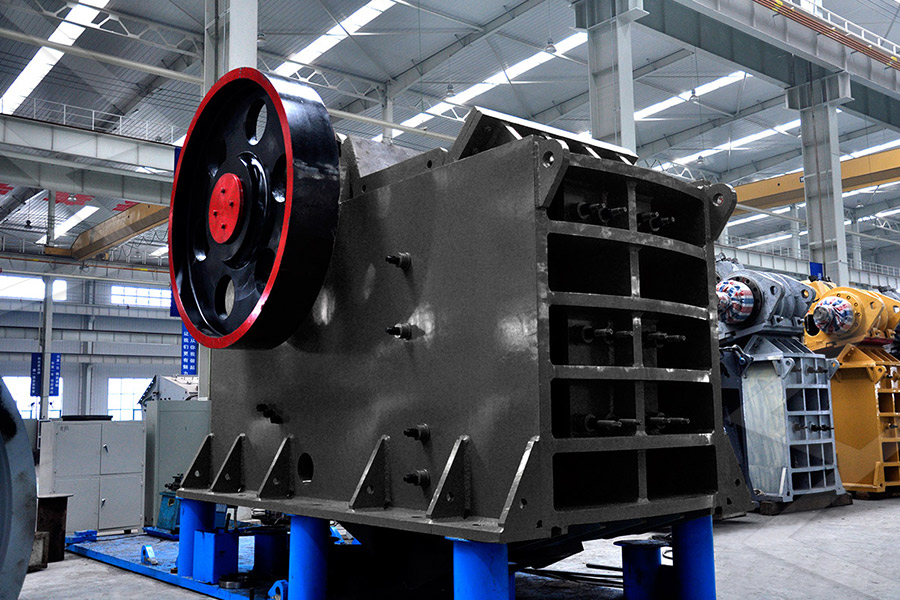

Jaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates There are also primary and secondary types of these crushers2023年2月28日 Secondary crushing is the second stage in the comminution process and involves breaking down the material further into smaller pieces that can be handled by the tertiary crushers The purpose of secondary crushing is The Complete Guide to Primary Crushing, 2024年1月1日 Jaw crusher is crushing equipment that works with two jaw plates, one fixed and the other movable The movable jaw plate approaches the fixed jaw plate periodically to Jaw Crusher SpringerLinkFor crushing middle hard to hard and abrasive materials in primary and secondary crushing applications for low and high capacities Singletoggle jaw crushers are characterized by the swing jaw being suspended directly on the Single Toggle Jaw Crusher thyssenkrupp Polysius

Nordberg C120 Jaw Crusher Jaw Crusher For Sale Pilot

Nordberg® C120™ jaw crusher is generally used as primary crusher, as the first step of size reduction It prepares the feed for the secondary crusher in a crushing and screening process 2018年6月1日 This paper compares the use of jaw and impact secondary crushing for producing coarse recycled aggregates from concrete wastes, obtained from road pavement and Concrete aggregates properties crushed by jaw and impact secondary 2024年2月6日 Picture this: in a single toggle jaw crusher, the main engine shaft is installed at the very top Now, the swing jaw hangs on this shaft, leading to some fancy jaw movement that’s a bit more complex than what you’d find in Understanding Types of Jaw Crusher: A 2024年7月15日 Jaw crusher machine installation cost is relatively higher than gyratory crusher while its investment and maintenance cost is much lower than that of gyratory crusher Jaw crusher and gyratory crusher process granite What Are the Differences Between The 7 Types

.jpg)

Jaw Crushers – MEKA

For this reason, the crushed rock produced by the jaw crusher is unsuitable as an aggregate in concrete, especially in the construction sector If the rocks produced by a jaw crusher are to be used in the construction sector, the internal Difference of jaw and impact crusher Use Jaw crushers are generally used for primary crushing, which breaks the large materials into suitable for the secondary crusher such as cone crusher In the quarry plant, impact crusher is mainly used for fine crushing operations, cooperative crushing with jaw crusherJaw Crusher vs Impact Crusher Which Better JXSC Mine2024年7月17日 Jaw Crusher Jaw crushers use the compressive and bending action of a fixed jaw plate and a movable jaw plate to crush materials of various hardnesses When the two jaw plates come together, the material is crushed; when the plates move apart, material smaller than the discharge opening is released from the bottom The crushing action is Types of Crushers: Choosing the Right One for Each StageJaw Crusher Supplier, Hammer Cruser, Cone Crusher Manufacturers/ Suppliers Henan Fuyuan Machinery Manufacturing Co, Ltd Menu Sign In Jaw Crusher Gravel Granite Small Jaw Rock Crusher Gold Secondary Jaw Crusher Equipment with Diesel Engine Limestone US$3,2000035,41000 1 Set (MOQ) Large Mobile Portable Stone Jaw Crusher Machine Jaw Crusher Manufacturer, Hammer Cruser, Cone Crusher

.jpg)

Jaw Crusher for Sale in Indonesia Primary Stone Crusher

Jaw Crusher di Indonesia adalah alat penghancur utama yang disukai Primary Jaw Crusher memiliki karakteristik rasio penghancuran yang tinggi, ukuran produk yang seragam, struktur sederhana, kinerja kerja yang stabil, perawatan yang mudah, biaya operasi 2017年1月7日 MTH Series Secondary Jaw Crusher Stone Crusher 2006 MTH Series Secondary Jaw Crusher Stone Crusher 3006 MTH Series Jaw Crusher Mini Stone Crusher; View More Show All Categories Product Videos VS 1454 Wire Mesh Design Vibrating Screen Get Best Quote Vibrator Screening Machine Get Best Quote Secondary Jaw CrusherVibrating Screen and Rhino Series Secondary Jaw Crusher Crushers Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jawcrusher Construction Jaw crushers are heavyduty machines and hence must be robustly constructed The main frame is often made from cast iron or steel, connected with tiebolts It is commonly made in sections so that it can be transported Jaw Crusher an overview ScienceDirect Topics2016年2月28日 The jaw crusher does not lose any of its “newcondition” throw when the babbitt wears in the main, or in the pitman, bearings The jaw crusher will handle sticky,’or dirty feed better than the gyratory, there being no diaphragm below the crushing chamber on which such material can pack Routine maintenance and repair jobs are generally Gyratory VS Jaw Crushers: Advantages Disadvantages

WHAT IS A JAW CRUSHER? MEKA

We call the machine that performs the CRUSHING process a CRUSHING MACHINE or CRUSHER MEKA Size Reduction Machines WHAT IS A JAW CRUSHER? / JAW CRUSHER This is a type of crusher that is widely used in 2020年3月3日 Konark Jaw Crusher Secondary Jaw Crusher : Secondary Jaw Crusher Manufacturers, Secondary Jaw Crusher Exporter, Secondary Jaw Crusher Supplier, IndiaSecondary Jaw Crusher : Secondary Jaw Crusher 2024年11月24日 Hanlinsky SJ Series jaw crushers are mainly used for coarse crushing and medium crushing for mining, building materials and infrastructure construction In most cases, they are worked as primary crushers for making Sj Series Jaw Crushers for Primary or Secondary 2023年5月27日 Discharging size: The Jaw crusher is normally used for primary crushing which will give you a big crushing capacity and the output size is bigger but suitable for secondary crushing While cone crusher is for secondary and tertiary crushing stages, thus having a smaller discharging sizeJaw Crusher VS Cone Crusher (A Comparison From 7 Points)

Jaw Crusher Explained saVRee

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top ie the opening), and each jaw will have a 54inch width If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimension2024年2月20日 Jaw Crusher: Primary: Gold, Copper, Limestone: Up to 1200mm (48 inches) 150mm300mm (612 inches) High durability, suitable for hard materials: Impact Crusher: Secondary: Limestone, Asphalt, Gravel: Not exceeding 800mm (31 inches) Var down to 25mm (1 inch) High reduction ratio, good for soft to mediumhard materials: Cone Crusher: Secondary What's the Difference: Impact Crusher vs Jaw Crusher JXSC2021年4月8日 Jaw crusher masuk dalam kategori crusher primer, karena menghasilkan ukuran material yang lebih kecil Nantinya material yang lebih kecil tersebut akan diproses ke tahap selanjutnya Baca juga: Mengenal Jenis Alat Berat dan Mengenal Mesin Penghancur Batu Tipe Jaw Crusher yang 2023年6月29日 Both jaw crusher and roll crusher are simple structure and crush hard material by extrusion forceJaw crushers are mainly used for coarse crushing and medium crushing processes, and roller crushers are fine crushing machines Roll Crushers are designed to handle the primary, secondary and tertiary stage crushing of friable materials such as Jaw Crusher VS Roller Crusher Baichy

Secondary Jaw Crusher Manufacturer from Navi Mumbai

Stone Jaw Crusher are available in various sizes from 16x10, 22x10, 24x12, 24x18, 32x20, 36x28, 38x30, 42x32, 42x34, 32x07, 36x08, 42x08, 48x10 etcFor crushing middle hard to hard and abrasive materials in primary and secondary crushing applications for low and high capacities Singletoggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plateSingle Toggle Jaw Crusher thyssenkrupp Polysius5 天之前 Measurement of the crusher's closed side setting varies depending on the jaw profile that is being used and has an impact on the crusher's capacity and product gradation The following factors will enhance crusher capacity and Pex Series Fineness Jaw Crusher Mining Machine 2024年7月30日 Jaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square“Computer Aided Design of Jaw crusher” 911 Metallurgist

Jaw Crusher Price Guide: Everything Buyers Need

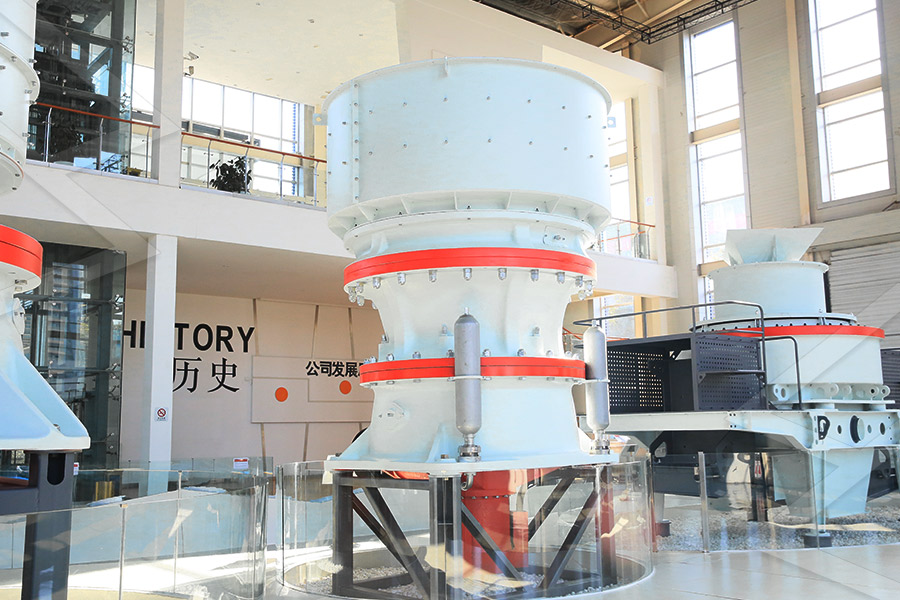

2024年4月25日 Size and Capacity: The size and the capacity of jaw crusher have a considerable effect on the price of the crusher A small jaw crusher having a 250x400mm feed opening and a capacity of 520 tons per hour will cost less 2024年3月20日 Cone crushers, on the other hand, are more often used in the secondary and tertiary crushing stages After the jaw crusher has done the primary crushing, the material gets fed into a cone crusher to be made even smaller Sometimes, several cone crushers might be used one after the other to get the product to the desired size and shapeUltimate Comparison: Jaw Crusher vs Cone Crusher JXSCCPC 4208 RHINO MARK II Single Toggle Stone Crusher have minimum wear tear of Toggle Plate, Hook Rod, Toggle Seat (Liner) and Spring due to incorporation of advanced crushing technology Features 1 Year Guarantee on All Parts ( Except Jaw PI , Side PI , Gutka Gutka Bolt) Extra heavy alloy steel shaft; Higer Production as Compared to Mark IRhino Series Secondary Jaw Crusher2021年4月12日 Occasionally, a Jaw Crusher may be applied as a secondary crusher Cone Crushers Cone Crushers are compressiontype crushers, which reduce material as it advances downward through the chamber (with the help of gravity and the weight above) by means of squeezing the material between a moving piece of steel (mantle) and a stationary piece (liner Downstream Crushing Options for Secondary, Tertiary and

.jpg)

Jaw Crusher Primary Crusher in Mining Aggregate JXSC

JXSC Jaw Crushers Advantages Features 40 years of manufacturing and engineering experience keep us innovative and knowledge in the rock break machines and its applications, which thus provide reliable industry rocks crushers and solutions for every customer using jaw crusher manufacturers JXSC machines to meet their production goalsThe jaw crusher Jaw Crusher EB 1612 Pro with a capacity range of 400 – 1,200 tph Jaw Crusher EB 1411 Pro with a capacity range of 300 – 950 tph preparing materials for further (secondary and tertiary) crushing They handle a variety of materials, including High efficiency crushing – FLS jaw crushers FLSmidth17 小时之前 PE Jaw Crusher Pe jaw crusher machine is mainly used for coarse crushing and medium crushing in the departments of mining, building materials and infrastructure construction Features kinglink's jaw crusher is engineered for even the toughest mining applications thanks to its heavyduty designPex300X1300 (PEX1251) Secondary Fine Jaw Crusher for 2013年3月17日 7 211 Tipe Stone Crusher Beberapa macam peralatan pemecah batu (stone crusher) meliputi : 1 Primary Crusher, biasanya menggunakan tipe crusher: a Jaw crusher (pemecah tipe rahang) Jaw crusher digunakan untuk mengurangi besar butiran pada tingkat BAB II TINJAUAN PUSTAKA 21 Mesin Pemecah Batu

Understanding Types of Jaw Crusher: A

2024年2月6日 Picture this: in a single toggle jaw crusher, the main engine shaft is installed at the very top Now, the swing jaw hangs on this shaft, leading to some fancy jaw movement that’s a bit more complex than what you’d find in 2024年7月15日 Jaw crusher machine installation cost is relatively higher than gyratory crusher while its investment and maintenance cost is much lower than that of gyratory crusher Jaw crusher and gyratory crusher process granite What Are the Differences Between The 7 Types For this reason, the crushed rock produced by the jaw crusher is unsuitable as an aggregate in concrete, especially in the construction sector If the rocks produced by a jaw crusher are to be used in the construction sector, the internal Jaw Crushers – MEKADifference of jaw and impact crusher Use Jaw crushers are generally used for primary crushing, which breaks the large materials into suitable for the secondary crusher such as cone crusher In the quarry plant, impact crusher is mainly used for fine crushing operations, cooperative crushing with jaw crusherJaw Crusher vs Impact Crusher Which Better JXSC Mine

.jpg)

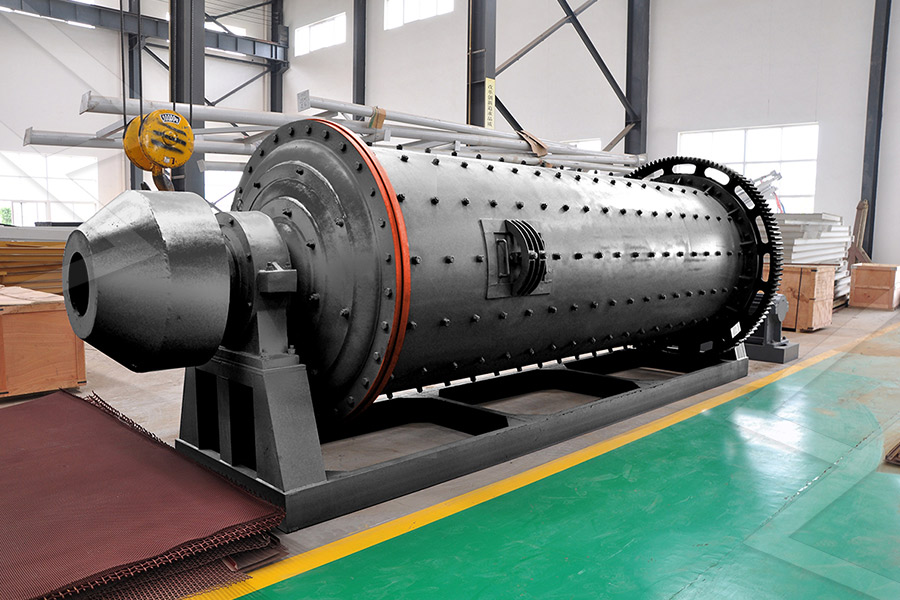

Types of Crushers: Choosing the Right One for Each Stage

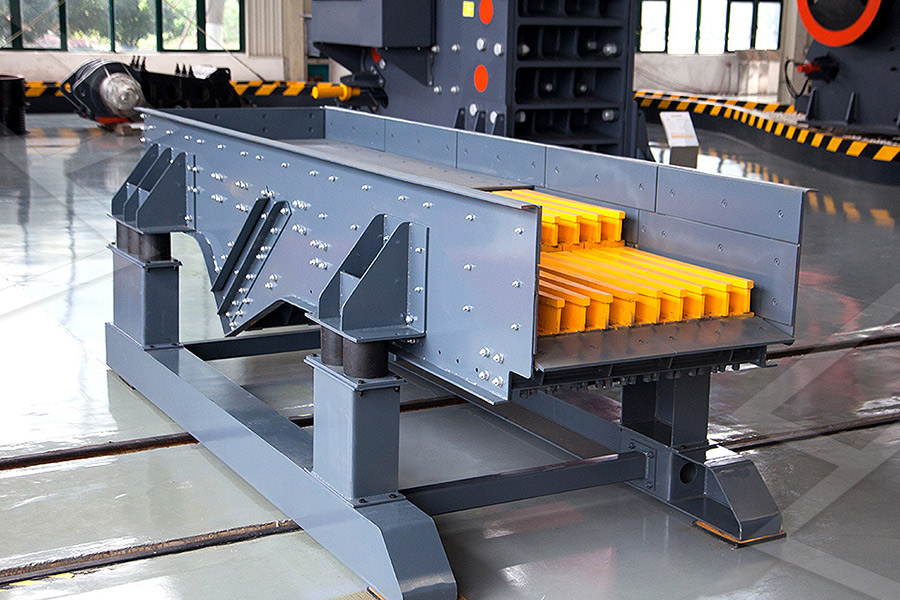

2024年7月17日 Jaw Crusher Jaw crushers use the compressive and bending action of a fixed jaw plate and a movable jaw plate to crush materials of various hardnesses When the two jaw plates come together, the material is crushed; when the plates move apart, material smaller than the discharge opening is released from the bottom The crushing action is Jaw Crusher Supplier, Hammer Cruser, Cone Crusher Manufacturers/ Suppliers Henan Fuyuan Machinery Manufacturing Co, Ltd Menu Sign In Jaw Crusher Gravel Granite Small Jaw Rock Crusher Gold Secondary Jaw Crusher Equipment with Diesel Engine Limestone US$3,2000035,41000 1 Set (MOQ) Large Mobile Portable Stone Jaw Crusher Machine Jaw Crusher Manufacturer, Hammer Cruser, Cone Crusher Jaw Crusher di Indonesia adalah alat penghancur utama yang disukai Primary Jaw Crusher memiliki karakteristik rasio penghancuran yang tinggi, ukuran produk yang seragam, struktur sederhana, kinerja kerja yang stabil, perawatan yang mudah, biaya operasi Jaw Crusher for Sale in Indonesia Primary Stone Crusher2017年1月7日 MTH Series Secondary Jaw Crusher Stone Crusher 2006 MTH Series Secondary Jaw Crusher Stone Crusher 3006 MTH Series Jaw Crusher Mini Stone Crusher; View More Show All Categories Product Videos VS 1454 Wire Mesh Design Vibrating Screen Get Best Quote Vibrator Screening Machine Get Best Quote Secondary Jaw CrusherVibrating Screen and Rhino Series Secondary Jaw Crusher

.jpg)

Jaw Crusher an overview ScienceDirect Topics

Crushers Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jawcrusher Construction Jaw crushers are heavyduty machines and hence must be robustly constructed The main frame is often made from cast iron or steel, connected with tiebolts It is commonly made in sections so that it can be transported 2016年2月28日 The jaw crusher does not lose any of its “newcondition” throw when the babbitt wears in the main, or in the pitman, bearings The jaw crusher will handle sticky,’or dirty feed better than the gyratory, there being no diaphragm below the crushing chamber on which such material can pack Routine maintenance and repair jobs are generally Gyratory VS Jaw Crushers: Advantages Disadvantages