Equment Productivity Of Jaw And Impact Crushers

Capacities and performance characteristics of jaw crushers

1994年5月1日 The method presented can be used to estimate the capacities and power requirements of jaw crushers By using the data of EA Hersam and FC Bond’s equation for energy consumption in comminution, a method was developed to analyze the performance of2019年1月1日 This paper compares the use of jaw and impact secondary crushing for producing coarse recycled aggregates from concrete wastes, obtained from road pavement and Concrete aggregates properties crushed by jaw and impact 2020年6月1日 Jaw crusher performance can be optimised for increased aggregate quality Calculation of flakiness index hides variation of particle shape within a gradation Mechanical Influence of jaw crusher parameters on the quality of 2017年5月1日 In this study, a fundamental model of a jaw crusher has been developed The model is based on previous knowledge from studies of cone crushers applied to jaw crushers A fundamental model of an industrialscale jaw crusher

.jpg)

(PDF) Influence of jaw crusher parameters on the

2020年3月19日 Mechanical properties are least affected by the jaw crusher parameters, but sample preparation using laboratory crushing clearly affect mechanical properties The results from this study provide2020年2月28日 There are several factors that will enhance crusher capacity and performance In order to determine all these factors to design the proper primary crusher, many experimental Evaluating the Impacts of Jaw Crusher Design 2022年9月20日 In this study, the design parameters: plate profile, thickness, and the height of the jaw plate were optimised using ANSYS software These design parameters were varied to analyse deformation and(PDF) Optimisation of the swinging jaw design 2018年6月1日 This paper compares the use of jaw and impact secondary crushing for producing coarse recycled aggregates from concrete wastes, obtained from road pavement and (PDF) Concrete aggregates properties crushed by jaw and impact

Optimisation of the swinging jaw design for a single toggle jaw

2022年9月20日 In this study, the design parameters: plate profile, thickness, and the height of the jaw plate were optimised using ANSYS software These design parameters were varied to 2022年5月14日 Based on the mechanism and the type of forces applied crushers are basically classified into three types namely Jaw crusher, Cone crusher and Impact crushers However, Stone Crushers: A Technical Review on Significant Part of2021年11月22日 Jaw crushers and hammer mills used different methods for turning big rocks into small ones, and they are built for their distinct rolls in the reduction process Jaw Crusher Applications Rock crushing often is Jaw Crusher or Hammer Mill: Which is Right for 2020年9月20日 The 2S crushing consisted of primary and secondary crushers as Jaw and HSI (horizontal shaft impactor), respectively, while 3S crushing was composed of primary, secondary and tertiary crushers as (PDF) COMPARISON OF SECONDARY CRUSHING

What is an Impact Crusher and How Do They

When comparing impact crushers, cone crushers, and jaw crushers, it's essential to understand their distinct functionalities to determine the right equipment for your specific application As mentioned, an Impact Crusher is excellent for 2023年5月27日 Cone crushers and jaw crushers both perform well in quarries, aggregates plants, sand making plants, cement plants, etc However, many still do not know which one to choose To help you decide, now let's dive into the differences between cone crushers and jaw crushers 1 Different production characteristicsJaw Crusher VS Cone Crusher (A Comparison From 7 Points)2023年2月28日 Jaw crushers are one of the most commonly used crushing machines in the mining and quarrying industryThey are typically used as primary crushers to reduce large rocks, ores, and minerals into smaller, more manageable sizes The design of a jaw crusher plays a crucial role in its operation and efficiency, and this article will explore some of the key features The Importance of Jaw Crusher Design Features in Crushing 2022年9月20日 This study reports on the design optimisation of the swinging jaw crusher plate Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing During the crushing process, large and nonevenly distributed impact forces occur, resulting from uneven Optimisation of the swinging jaw design for a single toggle jaw

.jpg)

A Guide to Types of Jaw Crushers for Crushing Rocks and

2023年2月15日 It has more moving parts than other types of jaw crushers, which makes it more prone to wear and tear Additionally, the double toggle jaw crusher is more expensive than other types of jaw crushers Blake jaw crusher The Blake jaw crusher was first introduced in 1858 by Eli Whitney Blake This type of jaw crusher is still in use todayThis provides flexibility and allows for increased production capacity Superior Performance and Efficiency The key advantages of CONSTMACH mobile jaw and impact crushers are: The capacity to crush a wide range of rock types from soft to hard High sand ratio due to the special rotor design of the secondary impact crushersMobile Jaw And Impact Crushers Constmach2024年2月20日 What sets them apart is how they crush materials, the type of stuff they handle, and the size of the products they produce This piece dives into what makes impact crushers and jaw crushers different, looking closely at their characteristics, benefits, and ideal uses Knowing how they vary will help you choose the best one for your projectWhat's the Difference: Impact Crusher vs Jaw Crusher JXSC2023年2月21日 While jaw crushers have their own set of advantages and disadvantages, they are often compared with other types of crushers, such as impact crushers, cone crushers, and gyratory crushers In general, jaw crushers are a good option for applications where the material is relatively hard and where a high degree of reduction is requiredThe Ultimate Guide to Jaw Crushing Machines: Types

Impact Crusher vs Jaw Crusher: Which One is

Power – Impact crushers and jaw crushers require heavyduty motors to operate smoothly Make sure your power supply can handle the load expected from this equipmentSize – Impact crushers and jaw crushers come in different sizes to 2024年11月22日 Impact crushers are used to reduce the size of ore particles for further processing They are used as secondary crushers after jaw or gyratory crushers Recycling Jobs Recycling operations are helped greatly with impact crushers by breaking down demolition debris into reusable aggregates This helps in reducing landfill waste while sustaining Impact Rock Crushers: A Comprehensive Overview2024年3月4日 Essential Spare Parts for Impact Crushers: Blow Bars:Key components for impact crushers;Subjected to high impact forces;Available in various alloys to suit different applications; Impact Plates:Wearresistant plates that protect the crusher's feed and discharge openings;Regular inspection and replacement are essential for maintaining efficiency;Impact crusher application and spare parts introduction2024年7月15日 But the production of gyratory crusher is much higher than jaw crushers' Therefore, if you require a large production and no focus on particle shape, you can choose gyratory crusher, Vice versa If your production demands below 1000 t/h, jaw crusher is the best choice and performs better when being applied undergroundWhat Are the Differences Between The 7 Types of Crushers?

.jpg)

Understanding the Reduction Ratio of Jaw Crusher: How it

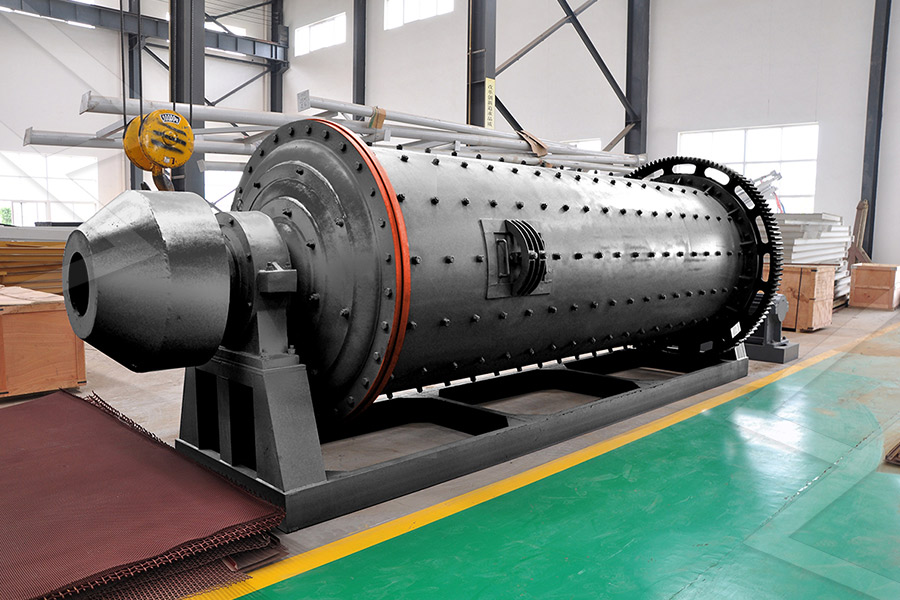

2023年2月28日 Overall, optimizing the reduction ratio and reducing the wear and tear of a jaw crusher can result in improved efficiency, increased productivity, and reduced maintenance costs By following the tips and steps outlined in this article, operators can ensure that their jaw crusher is operating at its best and producing highquality products with 2024年2月6日 Jaw crushers are absolutely vital in the mining world, helping us break down raw materials into something we can actually use With all the different kinds of jaw crushers out there, you’re sure to find the perfect one for the job, whether you need the tough single toggle or Blake crushers or the adaptable, onthego track mounted versionsUnderstanding Types of Jaw Crusher: A Comprehensive 2018年12月26日 3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 9 Rotary Breakers 48 10 Manganese Steel 49 There are four basic ways to reduce size of a material: by impact, by compression, by shear or by attrition Most crushers employ a combination of all these Construction, Working and Maintenance of Crushers for 2 天之前 The models and specifications of ZENITH jaw crushers are all complete There are coarse jaw crusher and fine jaw crusher for customers to choose, mainly used for the primary crushing operation of materials 4 production capacities Jaw crusher and impact crusher have different production capacities The max production capacity of ZENITH 7 Differences Between Jaw Crusher and Impact Crusher

What Are Jaw Crushers and How Do They Work? Oreflow

Doubletoggle jaw crushers In a doubletoggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and down Each shaft revolution causes the moving crusher jaw to close at the downstroke and open up during the upstroke The toggle is kept in place by springloaded tension rod6 天之前 Key Benefits of Using Jaw and Impact Crushers Together Using jaw and impact crushers in demolition projects is a great option Some of the benefits of this initiative include: Streamlined Operations; By using jaw and impact crushers together, a lot of unnecessary steps are reduced First, the huge blocks of hard material are put in the jaw Boosting Demolition Efficiency with Jaw Impact Crushers2023年2月23日 The differences between jaw crushers and impact crushers can have a significant impact on the efficiency, costeffectiveness, and productivity of your crushing operations, making it crucial to carefully consider the unique Jaw Crusher vs Impact Crusher: Which One 2024年3月20日 Jaw crushers and cone crushers are broadly utilized within the mining industry impact, and attrition forces The interparticle crushing action within the crushing chamber also contributes to the production of a more Ultimate Comparison: Jaw Crusher vs Cone

.jpg)

Modelling and simulation of particle breakage in

2004年12月1日 Left: A single particle just after impact with the rotor bar of a hammer crusher Right: A single particle leaving the rotor of a vertical shaft crusher; m p denotes the particle velocity2023年10月16日 Jaw crushers are commonly used in the mining and construction industry because of their ability to crush materials of different sizes There are several types of jaw crushers with varied characteristics and functions This feature saves time and boosts productivity Moreover, these machines are durable They can withstand harsh conditions The Mechanics of Crushing: Understanding the Jaw Crusher These energyefficient single toggle jaw crushers are ideal for multiple industries such as quarrying, mining, recycling and construction Can be used in the primary or secondary crushing station Ideal for multiple industries such as quarrying, mining, recycling and constructionCrushers Caldas Engineering and Manufacturing Services (Pty2023年2月23日 Introduction: Jaw crushers are powerful machines that are widely used in the mining, quarrying, and recycling industries These machines are designed to crush large rocks and ores into smaller pieces for further processing A jaw crusher consists of a fixed jaw and a movable jaw, with the latter being driven by an eccentric shaft that moves the jaw up and downUnderstanding Jaw Crusher Parts and Their Functions AGICO

Choosing the right jaw, cone or impact crusher for your needs

Choosing the correct jaw, cone, or impact crusher is the first step in optimizing your aggregate and recycling crushing operation and impact crushers from these two industry leaders covers everything from primary crushers with size and production capacities large enough for pit and quarry production to compact crushers small enough to fit The ability to achieve this affects production efficiency, operation costs, labour costs, project goals and the consistency of correctness of the final product Impact Crusher vs Compression Crushers – including Jaw Crushers Compression crushers are a category of crushers that include gyratory, cone, roll and jaw crushers In another When to Choose a Jaw Crusher VS Cone Crusher VS Impact 2024年3月31日 Cone crushers are widely used in the mining and aggregate industries for secondary and tertiary crushing applications They operate by compressing the material between a mantle and a concave, achieving finer particle sizes compared to jaw crushers Impact Crushers Impact crushers, as the name suggests, utilize impact force to crush materialsUnveiling the Features and Uses of Rock Crusher2024年11月8日 We provide both jaw and impact crushers, so regardless of the type of crusher you need, we’re sure we can help If you’re unsure of what you need, we’ll gladly assist you Please feel free to call our team on 0800 672 583 or use our contact page to reach paring Jaw Crushers vs Impact Crushers: Understand

.jpg)

Jaw Crusher or Hammer Mill: Which is Right for

2021年11月22日 Jaw crushers and hammer mills used different methods for turning big rocks into small ones, and they are built for their distinct rolls in the reduction process Jaw Crusher Applications Rock crushing often is 2020年9月20日 The 2S crushing consisted of primary and secondary crushers as Jaw and HSI (horizontal shaft impactor), respectively, while 3S crushing was composed of primary, secondary and tertiary crushers as (PDF) COMPARISON OF SECONDARY CRUSHING When comparing impact crushers, cone crushers, and jaw crushers, it's essential to understand their distinct functionalities to determine the right equipment for your specific application As mentioned, an Impact Crusher is excellent for What is an Impact Crusher and How Do They 2023年5月27日 Cone crushers and jaw crushers both perform well in quarries, aggregates plants, sand making plants, cement plants, etc However, many still do not know which one to choose To help you decide, now let's dive into the differences between cone crushers and jaw crushers 1 Different production characteristicsJaw Crusher VS Cone Crusher (A Comparison From 7 Points)

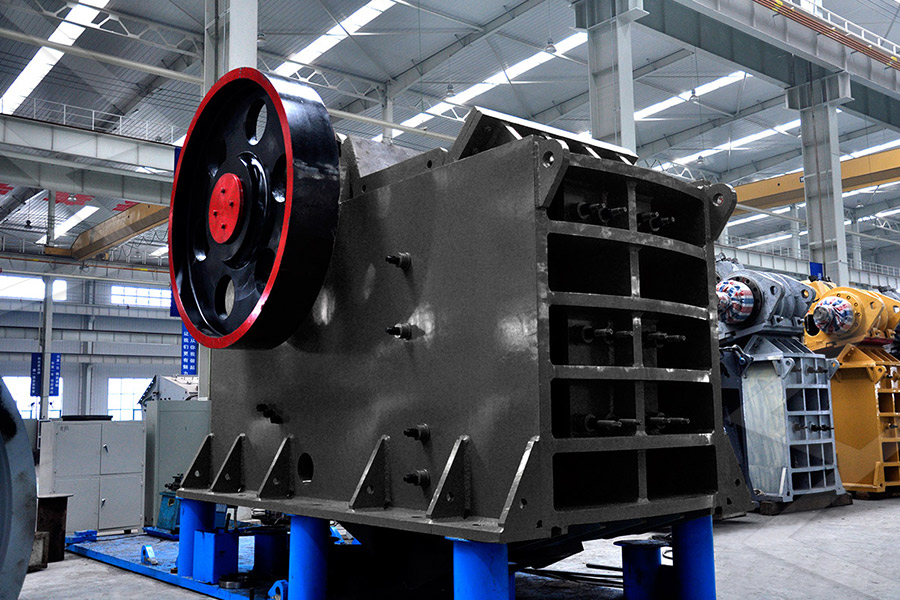

The Importance of Jaw Crusher Design Features in Crushing

2023年2月28日 Jaw crushers are one of the most commonly used crushing machines in the mining and quarrying industryThey are typically used as primary crushers to reduce large rocks, ores, and minerals into smaller, more manageable sizes The design of a jaw crusher plays a crucial role in its operation and efficiency, and this article will explore some of the key features 2022年9月20日 This study reports on the design optimisation of the swinging jaw crusher plate Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing During the crushing process, large and nonevenly distributed impact forces occur, resulting from uneven Optimisation of the swinging jaw design for a single toggle jaw 2023年2月15日 It has more moving parts than other types of jaw crushers, which makes it more prone to wear and tear Additionally, the double toggle jaw crusher is more expensive than other types of jaw crushers Blake jaw crusher The Blake jaw crusher was first introduced in 1858 by Eli Whitney Blake This type of jaw crusher is still in use todayA Guide to Types of Jaw Crushers for Crushing Rocks and This provides flexibility and allows for increased production capacity Superior Performance and Efficiency The key advantages of CONSTMACH mobile jaw and impact crushers are: The capacity to crush a wide range of rock types from soft to hard High sand ratio due to the special rotor design of the secondary impact crushersMobile Jaw And Impact Crushers Constmach

What's the Difference: Impact Crusher vs Jaw Crusher JXSC

2024年2月20日 What sets them apart is how they crush materials, the type of stuff they handle, and the size of the products they produce This piece dives into what makes impact crushers and jaw crushers different, looking closely at their characteristics, benefits, and ideal uses Knowing how they vary will help you choose the best one for your project2023年2月21日 While jaw crushers have their own set of advantages and disadvantages, they are often compared with other types of crushers, such as impact crushers, cone crushers, and gyratory crushers In general, jaw crushers are a good option for applications where the material is relatively hard and where a high degree of reduction is requiredThe Ultimate Guide to Jaw Crushing Machines: Types